Series - C

Automatic extinguishing systems

Installing a C-Series fire suppression system can provide a fast and effective response to fire on all types of equipment. The system is fully customizable and provides the features and functions that are necessary to protect a wide range of applications.

Enclosed and semi-enclosed spaces that are out of sight have an increased risk of fire and can lead to devastating consequences such as property damage, business interruption or, in the worst case, loss of life.

Engine rooms, server rooms, electrical cabinets, electrical generators and similar facilities are some examples of where such a fire can occur.

The pneumatic system operates automatically and independently of any power source, which is a key advantage as the system is able to automatically control and suppress a fire in the premises even when there are no people present. The system operation is based on pneumatic detection line technology, which is sensitive to high temperatures and allows the system to discharge immediately upon detection of a fire.

The electronic system has a customizable system operation that can be automatic, manual or a combination of both. There is also the option to delay discharge or only manual discharge if the system is in an occupied area. Electronic systems can be adapted for devices with higher operating temperatures.

Depending on the type of application, the systems are supplied in various modifications, such as:

- System type: DLP or ILP

- Agent type: gas (FK-5-1-12 or HFC-227ea), foam, powder

- Extinguishing agent tank volume: various volumes depending on the type of extinguishing agent.

- Several detection options

- Components and mounting material: distribution pipes, couplings, connectors, brackets

- Optional components: alarm panels, pressure switches, signaling devices, manual actuators, backup power units.

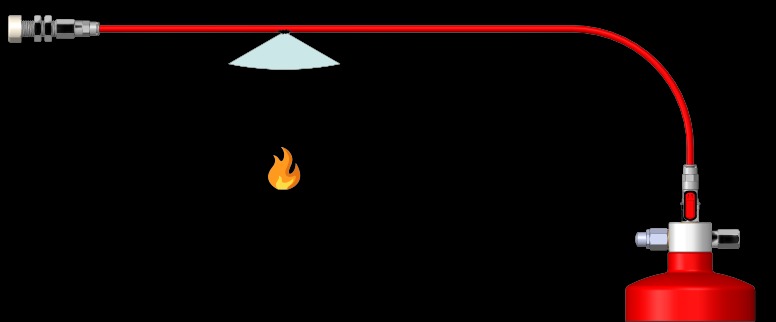

Direct low pressure system (DLP)

The DLP system is referred to as direct, which means that the activation and distribution of the extinguishing agent is provided by a detection hose. The system works by detecting a fire and applying the extinguishing agent directly using a detection hose attached to the valve of the pressure vessel. The detection hose is located in the protected space and is under constant pressure. When a fire occurs, the detection hose is damaged by the effects of fire and high temperature. When the detection hose bursts, the agent is released through an opening made directly at the source of the fire, applying the extinguishing agent directly to the fire. A pneumatic detection system can be independent of any electrical source and works solely on physical principles. The DLP system can also be electronically monitored using a pressure switch. The direct system is suitable for smaller applications and combines easy installation with simple operation.

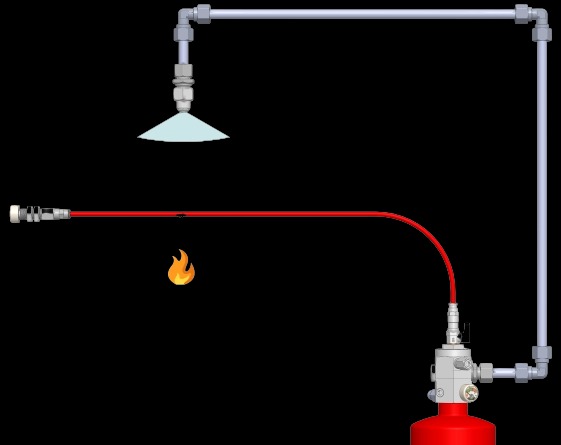

Indirect low pressure system (ILP)

The ILP system is called indirect, which means that it is activated by a breach in the detection hose or sensor and the extinguishing agent is distributed via separate lines to the nozzles. The fire extinguishing system works by detecting heat through a detection hose connected to a valve on the container. The hose is located in the protected area and is under constant pressure, which keeps the piston of the container valve closed. In the event of a fire, the hose degrades due to the action of fire and high temperature. The detection hose bursts and the pressure in the detection circuit drops, opening the valve on the container. The fire extinguishing system is activated and the entire extinguishing agent is discharged through the nozzles. A pneumatic detection system can be independent of any electrical source and works only on physical principles.

An indirect system is suitable for larger environments or where a specific application of the agent is required. This system also allows for various modifications by adding optional components such as manual activation, detectors, control panels for improved operability and system control. Selected ILP systems can be electronic and include an electric solenoid for triggering. This can be achieved by using linear heat detection, smoke and heat detectors or by connecting to a fire protection control panel with a GSM module. The electronic detection and activation circuits can be fully monitored by the BlazeCut reporting panel.